Concentric overburden drill system

Brief introduction of Concentric overburden drill system

The concentric overburden drill system consists of three parts: central pilot bit, casing shoe and symmetrical ring bit. The central pilot bit drills away the center part of the hole and guides the drill string, incorporated with a sacrificial symmetrical ring bit make a full face drill bit. The casing shoe is welded or threaded to a casing pipe, which is pulled down by the impact of the DTH hammer and central pilot bit. The symmetrical ring bit and casing shoe assembly is locked into central pilot bit with a hammer shank, and the ring bit is to drill the segment the casing to advance down the hole. The pilot bit’s upper shoulder engages the shoulder of the casing shoe.

DTH hammer’s impact energy is transferred through the pilot and ring bits, crushing rock, part of impact energy advances casing. On completion of drilling and casing, the drill string with pilot bit is retrieved by a slight reverse rotation to unlock the bayonet coupling. The ring bit stays in the hole, and can be recovered only if the casing is retrieved. Drilling continues to the desired depth in the bedrock using a conventional drilling.

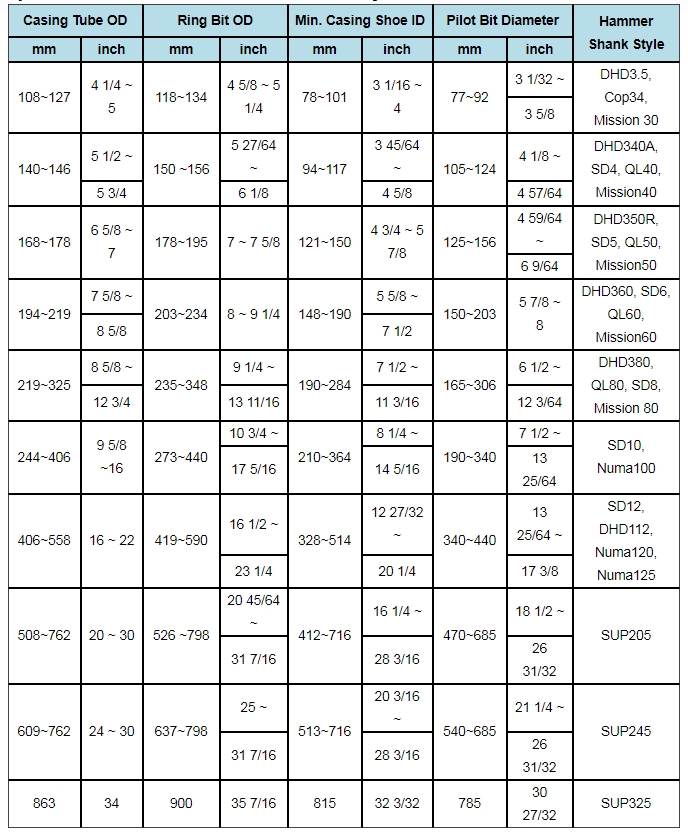

Specifications of concentric overburden drill system:

Picture of concentric overburden drill system:

Drilling through loose, unconsolidated material such as soil, clay, silt, sand, gravel, and boulders is the so-called overburden, which is often problematic due to the tendency of the earth to cave in behind the drill bit. The Symmetric Casing Drilling System is just to drill in rock formation where contains some such ovals and fractures, and it represents the latest technology in simultaneous overburden casing drilling systems.

Our concentric overburden drill system is designed to drill holes of many sizes, ranging from 108 to 863mm (4 1/4 to 34 in), at any angle (including horizontal), to any depth (beyond 100 meters) through unconsolidated formations simultaneously with casing.

The internal flushing grooves together with the built-in casing shoes gives a good seal to the button of the drilling hole, and thus minimizing the disruption of the surrounding of the drill hole. It makes the casing follow easy and the equipment and operation simple, and is recommended to a multitude of applications, such as micro-piling, underpinning, anchoring, marine work and horizontal drilling etc.

Features and Advantages:

Stable and reliable working performance

Full face head design for faster penetration and straighter hole

Less torque is required than eccentric drilling

Can drill in vertical, horizontal or any direction

Minimize disruption to the drilled hole

Effective cuttings removal

Unlocking-relocking easily

Easy to operate and system security

Varied ring bit diameters to suit different casing requirement

The less vibration of drill rig

Zhuzhou Xinpin Cemented Carbide Co., Ltd.

Ashary You

ashary@.xpczz.com

Wechat/Mob: +86 15197366167

http://www.xinpincarbide.com

To work with us is your best choice!