What is the Slitter cutting knives?

We are specialized in the manufacturing of carbide items.

With 100% virginal raw material, professional HIP sintering, advanced grinder and CNC technology, the carbide blades we produce are in high performance, high hardness, high precision, excellent durability and the quality is 100% guaranteed. The carbide blades have wide application that can be used used in automotive parts, aerospace, motorcycle parts, machinery and equipment manufacturing, and other parts turning, and so on.They also can be used for cutting paper, circuit board(PCB), fiber cement, woodwoking, etc.

The sizes are various and please kindly us the drawing.The sizes can be customized upon request.

What is the Application?

The carbide circular blades for Slitting Corrugated Board, carbide rotary blade for rubbers cutting, carbide blade for battery industry, carbide blades for Tobacco Machines, carbide circuit board cutting knife, carbide blades for metal cutting, carbide knife for Rewinder machines, carbide blades for chemical fiber cutting, carbide blades for printing industry, carbide cutter for paper industry, and carbide blades for other special range.

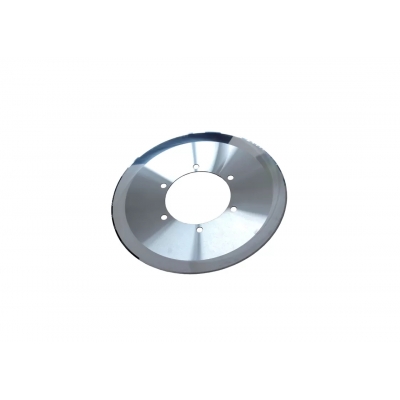

What does your Circle Slitter knives Look Like?

What is the Features of carbide slitter knives?

1: Highest grade Tungsten Carbide

They are manufactured to ensure perfect concentricity and balance.

This means you get a product that is safer, removes material faster.

2: Strictly quality control

It is guaranteed to provide the longest working life in the industry.

3: Have very good thermal & chemical stability

High precision, high intensity, excellent hardness,small thermal deformation.

4: High-quality carbide slitter knives and modern CNC machine.

With our precise producing process control, we can provide you best quality products with great competitive price to make you get more profits.

5: Large available stock at any time

6: With strict tolerance extent control

7: With submicron grain size

What is the specification of carbide slitter blades?

| Specs | diameter(гОЬ) | ID(гОЬ) | thickness(гОЬ) |

| 25×8×0.63-10B | 25 | 8 | 0.63 |

| 22×5×0.63-10B | 22 | 5 | 0.63 |

| 28×8×0.63-10B | 28 | 8 | 0.63 |

| 32×8×0.63-10B | 32 | 8 | 0.63 |

| 28×6×0.63-16B | 28 | 6 | 0.63 |

| 28×8×0.63-16B | 28 | 8 | 0.63 |

| 32×8×0.63-16B | 32 | 8 | 0.63 |

| Y28×8×0.63 | 28 | 8 | 0.63 |

Carbide slitter cutting knife manufactured to your drawings to meet your demands of particular stock removal.

How to produce the Carbide Slitter blades?

We can make chemical and geometry analysis for your carbide burs material and make grinding test in our professional laboratory center.