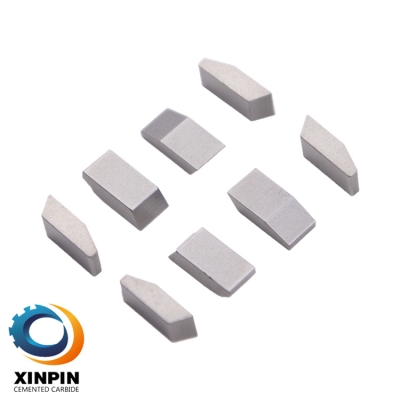

Cemented Tungsten Carbide Strips with 100% Virgin Materials

1. 100% virgin raw materials.

2. Various kinds of grades are availalbe based on customer‘s application.

3. We have professional advanced production line and inspeciton equipments to ensure high quality products.

4. Precision Ground and high polishing process

5. High wear resistance, high hardness and impact toughness

6. Advanced technology, precise grinding.

Grade Chart

| Grade |

Density (g/Cm³) |

Hardness (HRA) |

T.R.S (N/mm2) |

Recommended Cutting Application |

| SM02 | 15.0-15.2 | 94.5-94.8 | ≥2200 | For chipboard,MDF&HDF,Jaminated board,etc. |

| SM03 | 15.0-15.2 | 94.0-94.4 | ≥2500 | For veneer board,MDF&HDF,aluminum extrusions,etc. |

| SM06 | 14.9-15.1 | 93.6-94.0 | ≥2600 | For hardwood,copper,aluminum,plywood,MDF and Acrylic,etc. |

| SM07 | 14.8-15.0 | 93.2-93.6 | ≥2700 | For solidwood,hardwood,cooper,aluminum,plywood,etc. |

| SM09 | 14.6-14.8 | 92.4-92.8 | ≥2800 | For ceramic tile,solidwood,hardwood and various woodworking tools,etc. |

| SM10 | 14.2-14.4 | 92.0-92.5 | ≥3000 | For hardwood,Non-ferrousMetal,PCB circuit board and various woodworking tools,etc. |

| SM12 | 14.2-14.4 | 91.8-92.3 | ≥3000 | For stainless and alloy steel,etc. |

| XF5 | 14.9-15.1 | 91.2-92.0 | ≥2100 |

For solidwood,composite board and Non-Ferrous Metal,etc. |

| XF6 | 14.7-14.9 | 92.0-92.8 | ≥2200 | For solidwood,hardwood and composite board,etc. |

| XF8 | 14.5-14.7 | 91.0-92.0 | ≥2300 | For construction formwork,Non-ferrous Metal and various woodworking tools,etc. |

| XF10 | 14.3-14.5 | 90.5-91.5 | ≥2400 | For wolidwood,hadwood and various woodworking tools,etc. |

| XK10 | 14.8-15.0 | 90.5-91.5 | ≥2200 | For solidwood,hardwood,etc. |

| XK20 | 14.6-14.8 | 89.5-90.5 | ≥2400 | For softwood,solidwod,etc. |

| XP40 | 13.0-13.2 | 91.2-91.8 | ≥2800 | For alloy steel,stainless steel and high-manganese steel,etc. |

| XP30 | 13.1-13.3 | 91.4-92.0 | ≥2700 | For common steel,color steel tile,etc. |

| YG8C | 14.6-14.8 | 88.0-89.0 | ≥2700 | For weed,shrub,medium hard rock formation and natural stones,etc. |

| YG11C | 14.3-14.5 | 87.0-88.0 | ≥2600 | For marble,granite and various mining tools,etc. |

| YG15C | 13.9-14.1 | 85.5-86.5 | ≥2800 | For oil drill,stamping die material,etc. |

| YG20C |